In today’s world, having your Operation and Maintenance (O&M) data in a digital format allows for increased accessibility and traceability. Using more traditional recordings, such as on paper or with various Excel notebooks, increases the chances of error or loss of data. These methods also make it difficult to analyze the performance of the installed equipment.

exida’s latest product launch, SILstat™, is designed to provide users with a tool to manage and maintain their O&M data for their installed safety systems and associated field devices.

SILstat allows for automatic data transfer via an exSILentia project file, reducing setup time and costs. If you are already using exSILentia for your functional safety lifecycle needs, starting to use SILstat is easy!

Even if you are not using exSILentia, SILstat allows for data transfer from any third-party system through an Application Programming Interface (API) with data mapping and recording approach noted in a Data Philosophy Document.

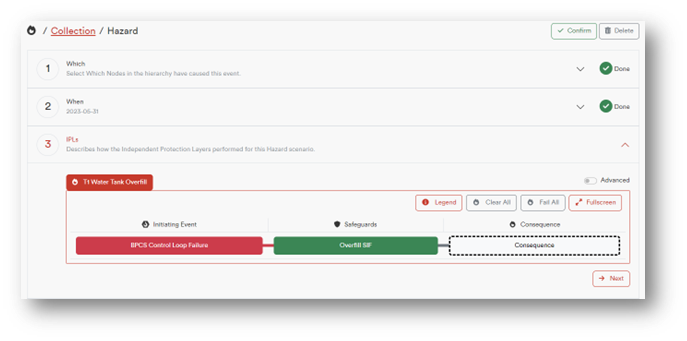

This screenshot shows SILstat’s Collection workflow. Users can collect different lifecycle events through the program, like a Hazard event.

SILstat’s data is shown in context through your Plant Hierarchy which outlines your plant’s units and devices in a navigation tree. All changes are traceable.

SILstat is accessible on a computer, laptop, or tablet when connected to the Internet.

For more information, please visit exida.com/SILstat or reach out to your local exida representative.